Trends Shaping Semiconductor Machinery Production Processes

by Suntop

2025-12-02

The semiconductor industry is at a pivotal moment. Rapid advancements in technology are reshaping production processes.

Semiconductor machinery manufacturing is evolving to meet new demands. The push for smaller, more efficient devices is relentless.

Automation and AI are now integral to manufacturing. These technologies enhance precision and efficiency in production.

Environmental concerns are also influencing manufacturing practices. Companies are adopting greener methods to reduce their carbon footprint.

The rise of IoT and 5G is driving innovation. These technologies require advanced semiconductor production equipment.

Semiconductor tool manufacturers are focusing on cost reduction. They aim to maintain quality while lowering production expenses.

The global market for semiconductor equipment is expanding. Significant growth is projected in the coming years.

Industry professionals must navigate these changes. Understanding trends is crucial for staying competitive in this dynamic field.

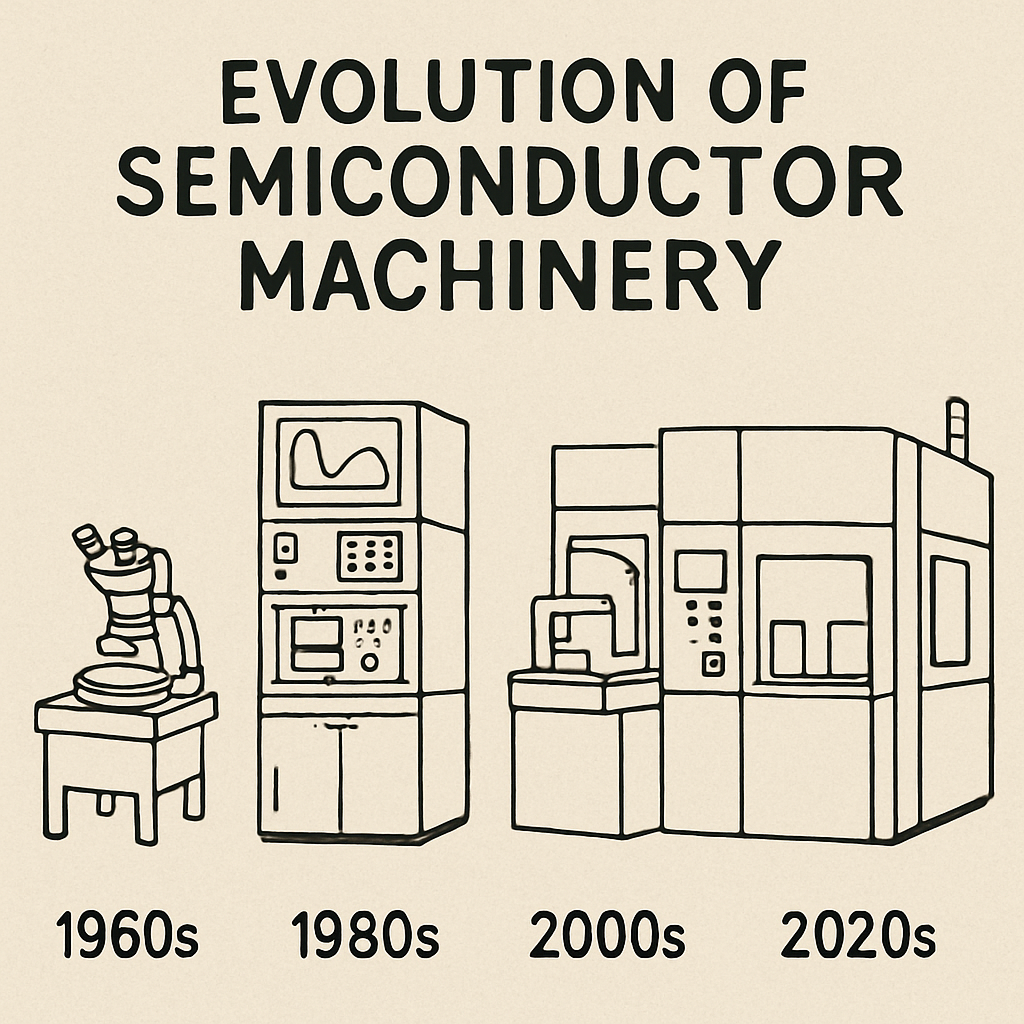

The Evolution of Semiconductor Machinery Manufacturing

Semiconductor machinery has undergone a significant evolution. Originally, the industry relied on basic tools. These tools have transformed into sophisticated equipment over time.

Innovations have propelled manufacturing into a new era. The focus has shifted to precision and efficiency. Today’s semiconductor machines are far more advanced than before.

Several key factors have driven this evolution:

- Continuous demand for smaller, faster devices.

- Integration of automation and machine learning.

- Advancements in semiconductor processing equipment.

Industry 4.0 is now a driving force behind change. This new phase emphasizes smart, connected manufacturing. IoT and data analytics play pivotal roles in optimizing processes.

Semiconductor tool manufacturers are adapting rapidly. They must innovate to keep pace with technology shifts. Evolution in semiconductor manufacturing equipment is a response to these pressures.

Understanding these changes requires a grasp of history. The past influences current production strategies and future trends. The machinery of today stands on the shoulders of past innovations.

Key Drivers of Change in Semiconductor Production Technology

Several dynamic factors shape semiconductor production today. These drivers influence the development and deployment of machinery. Understanding them is crucial for industry insiders.

A prime driver is consumer demand. People want smaller, more efficient electronic devices. This demand compels manufacturers to innovate constantly.

Technological advancements play a critical role. New technologies like AI and robotics enhance production. They streamline processes and improve accuracy.

Here are some key drivers transforming semiconductor technology:

- Increasing need for high-speed connectivity.

- Growth of AI and IoT applications.

- Advances in semiconductor machine precision.

Environmental concerns also drive innovation. Companies strive for more sustainable production methods. Green manufacturing practices are becoming standard in the industry.

Additionally, global competition encourages rapid progression. Companies must innovate to remain competitive. The market is highly dynamic, demanding constant evolution.

In summary, consumer demand, technological advancements, and environmental imperatives are pivotal. These factors shape the future of semiconductor production technology. Manufacturers must adapt to these forces to stay ahead.

Automation, AI, and Smart Manufacturing in Semiconductor Equipment

Automation is reshaping semiconductor manufacturing profoundly. Machines now perform tasks with minimal human intervention. This shift enhances efficiency across production lines.

Artificial Intelligence (AI) is central to this transformation. AI algorithms enable predictive maintenance and real-time adjustments. They help identify and solve issues before they escalate.

Smart manufacturing further integrates technology into processes. This approach ensures optimal performance through data-driven decisions. It enhances both productivity and quality in manufacturing.

Key features of AI and smart manufacturing:

- Real-time process monitoring.

- Automated quality control measures.

- Predictive maintenance systems.

These technologies reduce human error, fostering consistent production. They ensure high-quality outputs, meeting the precise demands of the semiconductor industry.

Furthermore, automation supports scalable production. It allows companies to quickly adjust to market demands. This flexibility is crucial in a competitive landscape.

AI and smart manufacturing also enhance data collection. Extensive data drive improvements and innovation. Insights from data shape future production strategies.

In conclusion, automation, AI, and smart manufacturing are vital. They streamline processes and elevate efficiency. Embracing these technologies is essential for modern semiconductor production companies.

Advanced Materials and Miniaturization in Semiconductor Machines

The semiconductor industry is at the forefront of material innovation. Advanced materials are crucial for enhancing machine performance and capabilities. These materials facilitate smaller, faster, and more efficient chips.

Miniaturization is a significant trend shaping the industry. Reducing the size of semiconductor components is critical for modern applications. This trend supports the development of compact and powerful devices.

Key advancements in materials and miniaturization include:

- Use of novel substrates like silicon carbide and gallium nitride.

- Development of high-k dielectrics for better insulation.

- Introduction of 3D packaging for more efficient designs.

These innovations not only improve performance but also reduce power consumption. Efficient energy use is vital for sustainable technology progress. Smaller components lead to less heat generation and increased device lifespan.

Miniaturization also expands potential applications. It allows for integration into various new technologies. This includes areas like wearable tech, IoT, and advanced computing systems.

Ultimately, advanced materials and miniaturization are driving forces. They enable breakthroughs that redefine possibilities in semiconductor technology. As these trends progress, they will continue to reshape the landscape of semiconductor machinery manufacturing.

Sustainability and Green Manufacturing Practices

The semiconductor industry faces rising pressure to adopt green practices. Environmental sustainability is becoming a core focus in manufacturing processes. Companies aim to reduce their carbon footprint while maintaining productivity.

Efforts towards sustainability involve using energy-efficient processes. This includes minimizing waste and optimizing resource use. Manufacturers are investing in technologies that lower emissions and save water.

Key sustainable practices being adopted include:

- Recycling and reusing materials to cut waste.

- Switching to renewable energy sources for production.

- Implementing closed-loop systems to conserve resources.

Corporate responsibility plays a significant role in these changes. Companies are not only meeting regulatory standards but also exceeding them. This proactive approach helps improve their market reputation and appeal to eco-conscious customers.

Green practices often lead to cost savings over time. They enhance efficiency and reduce reliance on scarce resources. Sustainability, though challenging, is proving to be beneficial both environmentally and economically.

As the industry evolves, a continued focus on green manufacturing will be essential. Embracing these practices can drive innovation and secure a competitive edge. The path to sustainability is clear, and the benefits continue to grow.

Digital Twins, IoT, and Data Analytics in Semiconductor Tooling

The integration of digital twins, IoT, and data analytics is revolutionizing semiconductor tooling. These technologies offer new ways to streamline processes and improve efficiency. They enable real-time monitoring and predictive maintenance.

Digital twins create a virtual replica of machines. This allows for simulation and testing without risking actual equipment. Manufacturers can optimize performance by analyzing different scenarios.

The Internet of Things (IoT) connects semiconductor tools to a network. This connectivity facilitates seamless communication between machines and systems. Consequently, production processes become more synchronized and efficient.

Key benefits of these technologies include:

- Enhanced real-time data collection and analysis.

- Improved machine uptime through predictive maintenance.

- Increased flexibility in adapting to production changes.

Data analytics plays a vital role by processing vast amounts of information. It helps in identifying patterns and optimizing operations. This leads to improved yields and reduced downtime.

Ultimately, the integration of these technologies helps companies remain competitive. They can adapt quickly to market changes and innovate effectively. As the digital landscape grows, the semiconductor industry will continue to leverage these advancements for success.

Supply Chain Resilience and Geopolitical Influences

Supply chain resilience is becoming crucial in semiconductor machinery manufacturing. Recent global events have exposed vulnerabilities in supply chains. Companies are now focusing on building more robust networks.

Geopolitical influences also play a significant role in shaping this industry. Trade policies and international relations impact material availability and pricing. Semiconductor companies need to navigate these complexities carefully.

Key factors affecting supply chain resilience include:

- Geopolitical tensions altering trade routes and material access.

- Natural disasters affecting key manufacturing regions.

- The rise of protectionist policies in multiple countries.

To mitigate these risks, semiconductor equipment companies are adopting diversified sourcing. They are also investing in advanced forecasting technologies. These measures help in anticipating potential disruptions and ensuring smoother operations.

The focus is also on forming strategic alliances with global partners. By doing so, companies enhance flexibility and adaptability. These strategies allow semiconductor manufacturers to maintain a steady flow of materials, crucial in this dynamic industry landscape.

Challenges Facing Semiconductor Machinery Manufacturing

The semiconductor industry is facing several challenges that affect machinery manufacturing. One major issue is the persistent material shortages that slow production processes. These shortages can lead to delays and increased costs for manufacturers.

Additionally, the growing complexity of semiconductor devices requires more advanced machinery. This need for cutting-edge technology places pressure on capital resources and engineering talent. Companies must continuously invest in research and development to stay competitive.

Compounding these challenges are rising geopolitical tensions and regulatory hurdles. Export controls and tariffs can disrupt the supply chain and increase operational risks. Navigating these obstacles demands strategic planning and flexibility from companies in the semiconductor sector.

Key challenges include:

- Material and component shortages affecting production timelines.

- Increasing complexity and miniaturization of devices.

- Geopolitical factors influencing global trade and supply chains.

- Regulatory hurdles in various regions.

Addressing these challenges is critical for maintaining a competitive edge. Innovations in technology and strategic partnerships can provide some solutions. Companies are focusing on adapting quickly to mitigate these hurdles and continue growth in a fast-paced market.

The Role of Semiconductor Equipment Companies and Tool Manufacturers

Semiconductor equipment companies play a crucial role in advancing technology. They develop innovative machines and tools essential for chip production. These companies drive improvements in efficiency and precision.

Tool manufacturers are vital in the supply chain, focusing on quality and cost-effectiveness. They supply the necessary components for machinery construction. Without these precise tools, the production process would slow considerably.

Both segments face pressures to meet demand and innovate continuously. Collaboration between companies can lead to quicker technological advancements. Partnerships enable companies to share resources and expertise, fostering growth in the industry.

Key roles include:

- Developing next-generation machinery for chip fabrication.

- Focusing on reliability and high precision for tooling.

- Ensuring supply chain stability and quality control.

- Collaborating to innovate and solve industry challenges.

In summary, these companies and manufacturers are crucial for the semiconductor industry’s evolution. By working together, they ensure the seamless operation and development of critical technology.

Future Outlook: Trends to Watch in Semiconductor Production Equipment

The semiconductor industry is poised for significant transformation in the coming years. Emerging technologies and shifting consumer demands will shape these changes. Keeping an eye on these trends is crucial for industry players.

One key area of focus is increased energy efficiency in production machines. Equipment will need to consume less power and maintain high performance. Sustainability will also drive innovations in semiconductor fabrication tools.

Another area is the integration of AI and machine learning. These technologies will improve equipment operation and maintenance. Predictive analytics will become vital in avoiding machine downtimes.

Key trends to watch include:

- Enhanced energy efficiency in semiconductor tools.

- Greater integration of AI and machine learning.

- Development of more sustainable production practices.

- Adaptations to emerging technologies like quantum computing.

In summary, the semiconductor machinery sector will see rapid changes. Companies should adapt swiftly to these trends to remain competitive. The future promises exciting opportunities for innovation and growth.

Conclusion: Navigating the Next Era of Semiconductor Machinery

Navigating the evolving landscape of semiconductor machinery requires strategic foresight. Industry leaders must embrace innovation to stay competitive. This involves continuous research and development investment.

The integration of advanced technologies, such as AI and IoT, will be crucial. These tools offer opportunities to enhance efficiency and precision. They also help in overcoming present manufacturing challenges.

Furthermore, sustainability cannot be overlooked. Green manufacturing practices are becoming a priority. Companies must seek methods to reduce environmental impacts without compromising on performance.

Ultimately, the semiconductor industry will continue to be a driver of technological progress. Adapting to new trends is not just beneficial but essential for survival. Embracing change will lead to future successes.

The semiconductor machinery sector stands on the brink of a new era. This period promises to bring opportunities for those ready to innovate and adapt. By understanding and anticipating emerging trends, companies can lead the charge towards a brighter future.

SUNTOP

Founded in 2000, Suntop is one of the leading global distributors of electronic components, dedica ted to providing comprehensive procurement and supply chain services to the global electronics manufacturing industry. Our services include distribution, spot trading, PPV cost-saving projects, and inventory management. We not only offer high-quality products but also strive to assist our clients in achieving optimal solutions with minimal time and cost.

Suntop is a popular choice for those seeking electron devices and circuits due to their competitive pricing and reliable service. They cater to both small-scale hobbyists and large-scale manufacturers, ensuring that every customer finds what they need.