what is smt

by Suntop

2025-11-28

In the ever-evolving realm of electronics, technological advances have ushered in revolutionary changes in the way components are assembled and integrated into devices. One pivotal innovation that stands at the forefront of modern electronics manufacturing is Surface Mount Technology (SMT). Delving into the intricacies of SMT reveals why it holds such a critical position in today’s electronics industry.

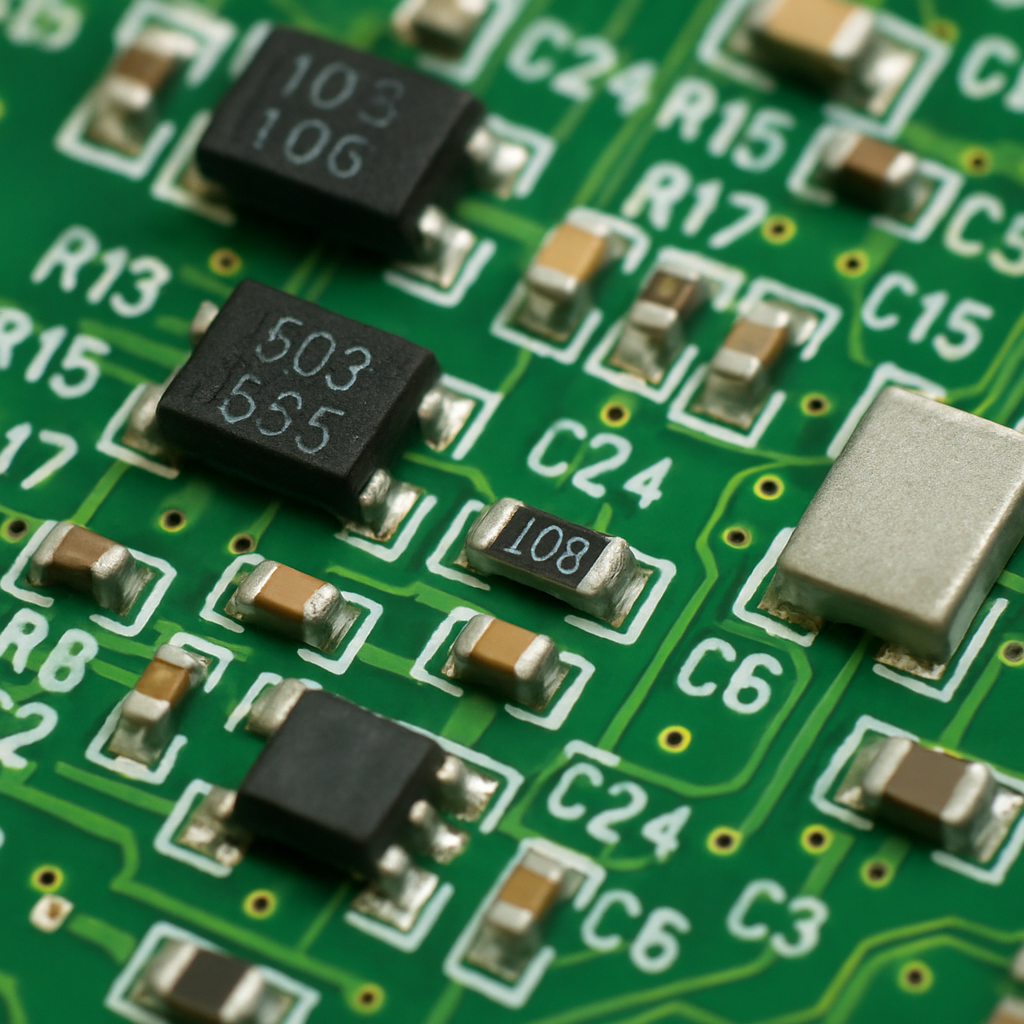

Surface Mount Technology, abbreviated as SMT, is a sophisticated method used to mount electronic components directly onto the surface of printed circuit boards (PCBs). This approach represents a significant shift from traditional through-hole technology, which involves inserting component leads into drilled holes on the PCB. SMT facilitates the creation of smaller, more compact, and efficient designs, thus transforming the landscape of electronic device manufacturing.

What Does SMT Stand For?

SMT stands for Surface Mount Technology. This acronym encapsulates a revolutionary approach to electronics manufacturing, one that has streamlined production processes and significantly enhanced efficiency. The advent of SMT marked a pivotal moment in the industry, enabling automation in production lines and setting new standards for manufacturing precision and speed. The impact of SMT on the electronics industry is profound, as it has become a cornerstone of modern manufacturing, influencing everything from the design of consumer gadgets to the development of complex industrial systems.

How SMT Revolutionized Manufacturing

The introduction of SMT revolutionized electronics manufacturing by providing a method that supports increased automation and precision. Prior to SMT, the assembly of electronic components was labor-intensive and prone to errors due to manual handling. With SMT, the use of automated machinery allows for precise placement of components, which not only speeds up the manufacturing process but also enhances product reliability. This shift towards automation has resulted in significant cost savings for manufacturers, as labor costs are reduced and production throughput is increased.

The Impact on Modern Electronics

The influence of SMT on modern electronics cannot be overstated. By allowing for the miniaturization of components, SMT has paved the way for the development of smaller, more portable devices. This technology has enabled manufacturers to meet the growing consumer demand for lightweight and compact electronics without compromising on performance. Moreover, SMT has enhanced the performance capabilities of electronic devices by improving signal integrity and reducing electrical interference, making it an indispensable component of today’s technology-driven world.

The Evolution of Electronics: From Through-Hole to SMT

Before the advent of SMT, electronic components were traditionally attached to circuit boards using through-hole technology. This method involved the manual placement of components, which was both time-consuming and limited the ability to miniaturize electronic devices. The emergence of SMT provided a solution to these challenges, marking a significant evolution in electronics assembly.

A Historical Perspective on Through-Hole Technology

Through-hole technology was the standard method of assembly for many decades, characterized by the insertion of component leads into pre-drilled holes on PCBs. This technique required significant manual labor and was inherently limited in terms of design flexibility. As consumer demand for smaller and more complex electronic devices grew, the limitations of through-hole technology became increasingly apparent, prompting the development of more efficient assembly methods.

The Transition to Surface Mount Assembly

Surface mount assembly represents a major advancement in the field of electronics manufacturing. This process involves the precise placement and soldering of surface mount components onto a PCB using automated machines. The shift to surface mount assembly brought about significant improvements in production speed and accuracy, as machines could place components with greater precision than human operators. This transition also facilitated the integration of more components onto a single board, leading to more compact and efficient designs.

The Advantages of SMT Over Through-Hole Technology

SMT offers numerous advantages over traditional through-hole technology, making it the preferred choice for modern manufacturers. One of the key benefits is the ability to produce smaller and lighter circuit boards, as components can be placed closer together without the need for drilled holes. Additionally, SMT improves electrical performance by reducing parasitic capacitance and inductance, which enhances signal transmission and circuit reliability. These advantages have cemented SMT’s status as a vital component of contemporary electronics manufacturing.

Advantages of Surface Mount Technology

SMT offers a multitude of benefits over traditional assembly methods, which have solidified its status as the preferred choice for manufacturers worldwide. The advantages of SMT extend beyond mere convenience, providing tangible improvements in design, performance, and cost efficiency.

Compact and Efficient Design

One of the primary advantages of SMT is its ability to support compact and lightweight designs. By eliminating the need for component leads and holes, SMT enables components to be placed in closer proximity, resulting in smaller and more efficient circuit boards. This compact design capability is particularly valuable in the development of portable electronic devices, where space is at a premium. The ability to pack more functionality into a smaller footprint allows manufacturers to create innovative products that meet the demands of modern consumers.

Enhanced Performance and Reliability

Surface mount components are known for their superior electrical performance, which can be attributed to the shorter lead lengths that reduce parasitic capacitance and inductance. This improvement leads to faster signal transmission and increased circuit reliability, which are crucial factors in high-performance applications. Furthermore, SMT’s precision placement and soldering processes minimize the risk of electrical faults, ensuring that devices operate consistently and reliably over their lifespan. The enhanced performance and reliability offered by SMT have made it an essential technology for industries that demand high-quality electronic solutions.

Cost-Effective Production and Automation

The SMT process is highly automated, which brings about substantial cost savings for manufacturers. By reducing the reliance on manual labor, SMT lowers production costs and increases efficiency. Automation also minimizes human error, resulting in higher quality products that meet stringent industry standards. The cost-effective nature of SMT allows manufacturers to remain competitive in a global market, as they can produce high-quality products at lower prices. Moreover, the scalability of SMT processes enables manufacturers to respond quickly to changes in demand, further enhancing their competitive advantage.

Key Components in SMT

Surface mount technology involves a diverse array of components and equipment that work in harmony to assemble electronic circuits efficiently and accurately. Understanding these key components is essential for grasping the full potential of SMT.

SMT Components: The Building Blocks

SMT components, also known as SMD (Surface Mount Devices), are specifically designed to be mounted directly onto the surface of PCBs. These components encompass a wide range of electronic parts, including resistors, capacitors, diodes, and integrated circuits (ICs). Each component type plays a crucial role in the functionality of the final product, contributing to the overall performance and reliability of the device. The variety of SMT components available allows for great flexibility in circuit design, enabling manufacturers to tailor their products to meet specific application requirements.

Specialized SMT Equipment and Machines

The successful implementation of SMT requires specialized equipment to carry out the assembly process. Key machines used in SMT include:

- Pick and Place Machines: These machines automatically position components onto the PCB with exceptional precision, guided by programmed data that ensures each part is placed correctly.

- Reflow Ovens: Used to solder the components to the board by heating the solder paste applied during assembly, creating a secure and lasting connection.

- Inspection Equipment: Automated Optical Inspection (AOI) and X-ray machines are employed to verify the quality and accuracy of the assembled PCBs, detecting any potential defects or misalignments.

Each piece of equipment plays a pivotal role in ensuring the efficiency and quality of the SMT process, allowing manufacturers to produce high-performance electronic devices consistently.

The Role of Automation in SMT

Automation is a central theme in SMT, as it enhances both the efficiency and accuracy of the assembly process. Automated machines are capable of handling a large volume of components with speed and precision that surpasses manual assembly methods. This automation not only improves production throughput but also ensures consistent quality across large batches of products. The integration of advanced software and machine learning algorithms further optimizes the SMT process, enabling real-time adjustments and improvements that enhance overall productivity.

The SMT Process: How It Works

The surface mount technology process involves several critical steps that ensure the successful assembly of electronic components onto a PCB. Each step is meticulously designed to maximize efficiency and quality, resulting in reliable and high-performance electronic products.

Step 1: Solder Paste Application

The SMT process begins with the application of solder paste to the PCB. This paste, composed of tiny solder balls suspended in a flux medium, acts as an adhesive to hold components in place and facilitates the soldering process. The application is typically performed using a stencil and a squeegee, ensuring that the paste is precisely deposited only in the required areas. Accurate solder paste application is crucial, as it directly impacts the quality of the solder joints and the overall reliability of the assembled product.

Step 2: Component Placement

Following solder paste application, components are accurately positioned onto the PCB using a pick and place machine. This machine utilizes sophisticated algorithms and programmed data to determine the exact locati0n for each component, ensuring precise placement. The speed and accuracy of modern pick and place machines allow for the rapid assembly of complex circuits, significantly reducing production times. The ability to handle a wide variety of component sizes and shapes further enhances the versatility of the SMT process.

Step 3: Soldering in the Reflow Oven

Once the components are placed, the PCB is transferred to a reflow oven for the soldering process. The reflow oven heats the assembly to specific temperatures, causing the solder paste to melt and form a permanent bond between the components and the PCB. The controlled heating profile of the reflow oven ensures that the solder joints are strong and reliable, preventing issues such as cold solder joints or component damage. The soldering step is critical to the integrity of the final product, as it establishes the electrical connections that enable the device to function.

Step 4: Inspection and Quality Control

After soldering, the assembled boards undergo rigorous inspection to ensure all components are correctly placed and soldered. Automated Optical Inspection (AOI) systems and X-ray machines are commonly used to detect defects such as misaligned components, insufficient solder coverage, or bridging between solder joints. This inspection process is essential for maintaining high quality standards, as it allows manufacturers to identify and rectify any issues before the product reaches the market. The emphasis on quality control in SMT ensures that the final products are reliable and meet customer expectations.

Applications of Surface Mount Technology

SMT is utilized in a vast array of applications across various industries, underscoring its versatility and efficiency. The widespread adoption of SMT is a testament to its ability to meet the diverse needs of modern electronic manufacturing.

Consumer Electronics: Driving Innovation

In the realm of consumer electronics, SMT plays a pivotal role in the manufacturing of devices ranging from smartphones to televisions. The technology enables the production of smaller, more powerful devices that cater to the increasing demand for portability and functionality. SMT’s ability to accommodate complex circuits within compact designs has driven innovation in the consumer electronics sector, allowing manufacturers to deliver cutting-edge products that enhance the everyday lives of consumers.

Automotive Industry: Enhancing Vehicle Performance

The automotive industry has embraced SMT for the production of electronic control units, sensors, and infotainment systems. These components are essential for enhancing vehicle functionality and performance, enabling features such as advanced driver assistance systems (ADAS), navigation, and connectivity. The reliability and precision of SMT components are crucial in the automotive sector, where safety and performance are paramount. The technology’s ability to support the integration of sophisticated electronic systems into vehicles has paved the way for the development of smarter and more efficient automobiles.

Medical Devices: Supporting Healthcare Advancements

SMT is a key enabler in the development of compact and reliable medical devices, such as diagnostic equipment and monitoring systems. The technology’s precision and reliability are critical in medical applications, where accuracy and consistency are essential for patient care. SMT allows for the miniaturization of medical devices, making them more portable and accessible for healthcare professionals and patients alike. The continued advancement of SMT technology is expected to support further innovations in the medical field, improving the quality and effectiveness of healthcare solutions.

Challenges and Considerations in SMT

While SMT offers numerous benefits, it also presents certain challenges that manufacturers must address to ensure successful implementation. Understanding these challenges is crucial for optimizing the SMT process and achieving consistent results.

Component Handling and Precision

SMT components are typically smaller and more delicate, requiring careful handling and specialized equipment to prevent damage during assembly. The precision required in placing these tiny components demands advanced machinery and meticulous process control. Manufacturers must invest in high-quality equipment and develop robust handling procedures to minimize the risk of component damage or misplacement. The challenge of handling SMT components underscores the importance of precision and expertise in the assembly process.

Thermal Management and Heat Dissipation

As SMT boards become more densely populated with components, managing heat dissipation becomes a critical consideration. Effective thermal management is essential to prevent overheating and ensure the longevity of the components. Manufacturers must employ strategies such as thermal vias, heat sinks, and advanced materials to dissipate heat efficiently. The challenge of thermal management is particularly pronounced in high-performance applications, where excessive heat can compromise device reliability and performance.

Overcoming Manufacturing Defects

Despite the precision and automation of SMT processes, manufacturing defects can still occur. Common issues include solder bridging, tombstoning, and insufficient solder joints, which can affect the performance and reliability of the final product. Manufacturers must implement rigorous quality control measures and continuously refine their processes to minimize these defects. The challenge of overcoming manufacturing defects highlights the need for ongoing research and development to enhance the capabilities and reliability of SMT technology.

SUNTOP

Founded in 2000, Suntop is one of the leading global distributors of electronic components, dedica ted to providing comprehensive procurement and supply chain services to the global electronics manufacturing industry. Our services include distribution, spot trading, PPV cost-saving projects, and inventory management. We not only offer high-quality products but also strive to assist our clients in achieving optimal solutions with minimal time and cost.

Suntop is a popular choice for those seeking electron devices and circuits due to their competitive pricing and reliable service. They cater to both small-scale hobbyists and large-scale manufacturers, ensuring that every customer finds what they need.

Conclusion: The Future of SMT

Surface Mount Technology has transformed the electronics manufacturing landscape, providing a pathway for innovation and efficiency. As technology continues to advance, SMT will remain a vital component in the development of cutting-edge electronic devices.

In understanding what SMT is, we also recognize the importance of ongoing research and development to overcome challenges and further enhance the capabilities of this technology. As industries demand more complex and compact solutions, SMT will undoubtedly play a central role in shaping the future of electronics. The continued evolution of SMT is expected to drive further advancements in electronic design and manufacturing, paving the way for a new era of technological innovation.