what does solder flux do?

by Suntop

2025-10-21

What is flux do?

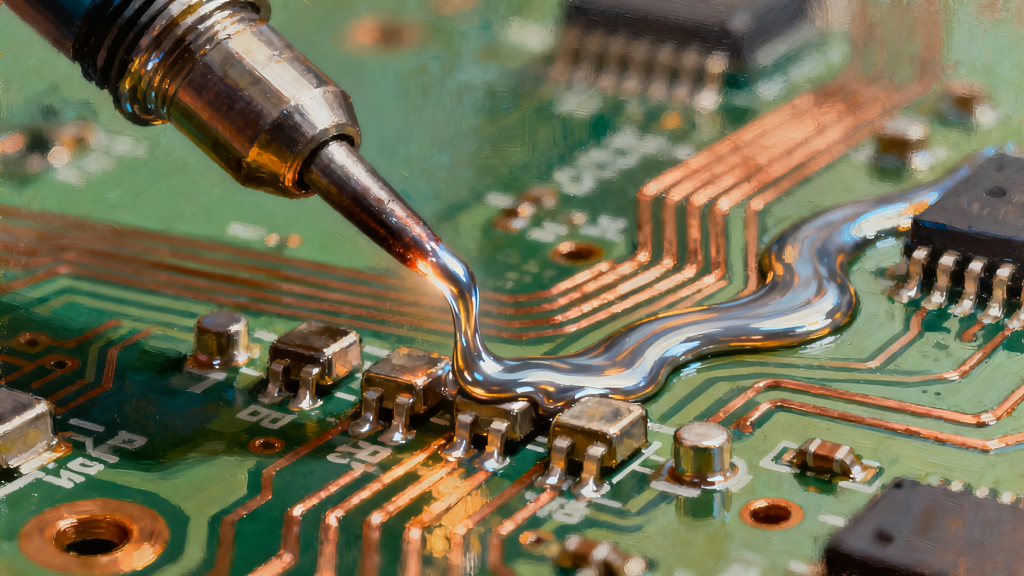

Soldering is a crucial skill in electronics and metalwork. It involves joining metal parts using a filler metal. But what ensures a strong, reliable connection? The answer is solder flux.

Solder flux is a chemical agent that plays a vital role in the soldering process. It cleans metal surfaces, removing oxidation and impurities. This ensures a clean area for the solder to adhere to.

Without flux, soldering can be challenging and unreliable. It helps the solder flow smoothly, creating a strong bond. Different types of flux are available, each suited for specific tasks.

Understanding what solder flux does is key to mastering soldering. This guide will explore its functions, types, and tips for effective use.

What Is Solder Flux?

Solder flux is a chemical agent used to make soldering easier. It prepares metal surfaces by removing oxidation. This process ensures a cleaner, more reliable solder joint.

Flux comes in various forms, each with distinct features. It can be found as liquid, paste, or solid. Each form serves unique applications, offering versatility for different soldering tasks.

Using flux improves the wetting process, allowing solder to spread and adhere effectively. Here are some key roles of solder flux:

- Cleans metal surfaces by removing oxidation.

- Helps solder flow evenly across the joint.

- Improves adhesion between metals.

Understanding the types and functions of solder flux helps in selecting the right one for your soldering needs.

How Does Solder Flux Work?

Solder flux plays a critical role in the soldering process. It begins by cleaning the metal surfaces, effectively removing oxidation. This step is crucial, as oxidation hinders solder adherence.

Once the oxidation is removed, flux aids in the wetting process. It reduces the surface tension of the solder, allowing it to flow smoothly. This ensures a strong connection between metal parts.

Flux also acts as a thermal conductor during soldering. It helps distribute heat evenly, preventing damage to components. This results in a more efficient soldering process.

Key functions of solder flux include:

- Cleaning metal surfaces from oxidation.

- Reducing surface tension for better solder flow.

- Acting as a thermal conductor.

By understanding these functions, one can appreciate the importance of solder flux in creating strong and reliable solder joints.

Types of Solder Flux

Solder flux comes in various types, each with specific applications. Choosing the right one is essential for effective soldering.

Rosin-based flux is widely used in electronics. Its non-corrosive nature makes it ideal for delicate components. This type is favored for its reliability.

Water-soluble flux offers easy clean-up but requires thorough washing. It can leave residue that corrodes if not cleaned completely. It’s best for applications where cleaning is manageable.

No-clean flux leaves minimal residue, making it perfect where cleaning is difficult. This flux is convenient but may not be ideal for every situation due to its higher activity level.

Different solder fluxes to consider include:

- Rosin-based flux for electronics.

- Water-soluble flux for easy cleaning.

- No-clean flux for minimal residue.

Understanding these flux types enables better decision-making for your projects. Selecting the appropriate solder flux enhances the quality and longevity of solder joints.

Why Is Solder Flux Important in Soldering?

Solder flux is crucial for achieving strong and reliable solder joints. It removes oxides from metal surfaces, ensuring a clean area for soldering. This preparation improves the bond between the solder and metals.

Flux plays a vital role in the wetting process. By reducing surface tension, it helps solder flow smoothly and adhere well. This results in more durable connections.

Using solder flux prevents common soldering issues like cold joints. A good bond is essential for both electrical and mechanical stability. Understanding the importance of flux is key to mastering soldering.

Key reasons for using solder flux include:

- Removing oxidation.

- Enhancing solder flow.

- Preventing common soldering issues.

How to Use Solder Flux: Step-by-Step Guide

Using solder flux correctly can make a big difference in soldering quality. With the right approach, even challenging tasks become easier and more reliable.

First, choose the right type of flux for your materials. Consider your project’s specifics and flux properties for the best results.

Next, apply a thin layer of flux to the metal surfaces you are joining. Use a brush, pen, or syringe for precision and control during application.

Finally, solder the joint while monitoring temperature closely. The heat will activate the flux, assisting solder flow and improving adhesion.

Steps to Use Solder Flux:

- Select appropriate flux for the task.

- Apply flux to clean metal surfaces.

- Heat to activate flux and solder effectively.

Soldering Tips for Best Results

Achieving top soldering results requires both practice and attention to detail. A few simple techniques can significantly enhance your soldering skills.

Keep your soldering iron tip clean and well-tinned. A shiny tip ensures efficient heat transfer and prevents oxidation.

Align components accurately before soldering for a strong bond. Good alignment minimizes the chances of creating faulty joints or causing bridging.

Monitor your soldering temperature to avoid damage. Too much heat can harm components, while too little might lead to weak connections.

Essential Soldering Tips:

- Maintain a clean soldering iron tip.

- Align components correctly.

- Control soldering temperature carefully.

Cleaning and Safety When Using Solder Flux

Cleaning after soldering is crucial, especially when using flux. Residue can affect component performance and cause circuit failures. Proper cleaning ensures longevity and reliability of your connections.

Safety measures are equally important. Solder flux can emit harmful fumes, necessitating well-ventilated areas or fume extractors. Use protective gear to avoid skin contact and respiratory irritation.

Key Cleaning and Safety Tips:

- Use isopropyl alcohol to clean flux residue.

- Ensure good ventilation during soldering.

- Wear protective gloves and eyewear.

Common Soldering Problems Solved by Flux

Solder flux is a vital tool for resolving several soldering issues. One common problem is the formation of cold joints, which flux helps prevent by promoting proper wetting. This ensures strong connections.

Another issue is bridging, where solder connects unintended areas. Flux minimizes this risk by allowing solder to flow smoothly only where needed.

Problems Solved by Flux:

- Cold joints due to poor wetting

- Bridging between adjacent paths

Understanding these issues and using flux appropriately can lead to more reliable soldering results. Proper flux application is a key element in achieving high-quality joints.

SUNTOP

Founded in 2000, Suntop is one of the leading global distributors of electronic components, dedica ted to providing comprehensive procurement and supply chain services to the global electronics manufacturing industry. Our services include distribution, spot trading, PPV cost-saving projects, and inventory management. We not only offer high-quality products but also strive to assist our clients in achieving optimal solutions with minimal time and cost.

Suntop is a popular choice for those seeking electron devices and circuits due to their competitive pricing and reliable service. They cater to both small-scale hobbyists and large-scale manufacturers, ensuring that every customer finds what they need.

Conclusion: Mastering Soldering with Flux

Mastering soldering requires understanding every element, especially solder flux. This humble compound plays a crucial role in achieving dependable connections.

From promoting good solder flow to reducing common issues, flux makes a big difference. By using the right type and amount, you can enhance your soldering skills significantly.