SUNTOP Quality Inspection

Industry-Leading Precision Inspection Technology

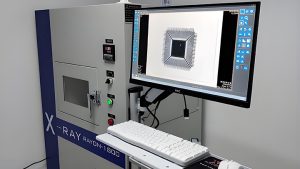

The SUNTOP electronic quality inspection team adopts industry-leading precision inspection technology, equipped with high-precision AI visual inspection equipment, which can accurately identify appearance defects such as solder joint abnormalities and tampered markings. It is combined with a high-resolution X-Ray non-destructive flaw detector to reveal hidden issues such as chip refurbishment and broken pins.

With a 3-second spectral analysis technology, the material composition and metal purity can be quickly verified.

By 2024, 5,800 batches of counterfeit components have been intercepted, with a value of more than 500,000 US dollars, and eight types of anti-counterfeiting technologies, including laser holography and quantum watermarking, have been analyzed. Relying on blockchain, SUNTOP enables data traceability across 30+ production stages throughout the entire supply chain.

This ensures that every component passes the three key checkpoints of AI eagle-eye inspection, X-ray internal analysis, and material composition verification, building an efficient defense line for customer supply chain security.

Visual Inspection

X-Ray Test

Electrical Test

Functional Test

Ultrasonic Test

Soldering Test

D-Cap Test

Encapsulation

Internationally certified to ISO 9001 and ISO 14001

Internationally certified to ISO 13485 and ISO 45001

Internationally recognized STRC certificate and ISO QAP certificate