Where Can Mechanical Systems Be Found?

by Suntop

2025-09-05

Mechanical systems are the unsung workhorses of modern life, powering industries, homes, and technology that many take for granted. Rarely do these systems function without the backbone of high-quality machine parts, mechanical parts, and parts for machines-components that dictate performance, durability, and efficiency.

For businesses relying on these systems, partnering with a trusted distributor like Suntop is pivotal. Founded in 2000, Suntop stands as one of the leading global distributors of electronic components, yet its expertise extends to supporting the sourcing of critical machine parts for the global electronics manufacturing industry.Through comprehensive procurement, spot trading, PPV cost-saving projects, and inventory management, Suntop ensures clients access top-tier mechanical parts with minimal time and cost, a value that resonates across every sector where mechanical systems thrive. Below, we explore the key industries where mechanical systems are indispensable, how parts for machines drive their success, and how Suntop elevates operational reliability.

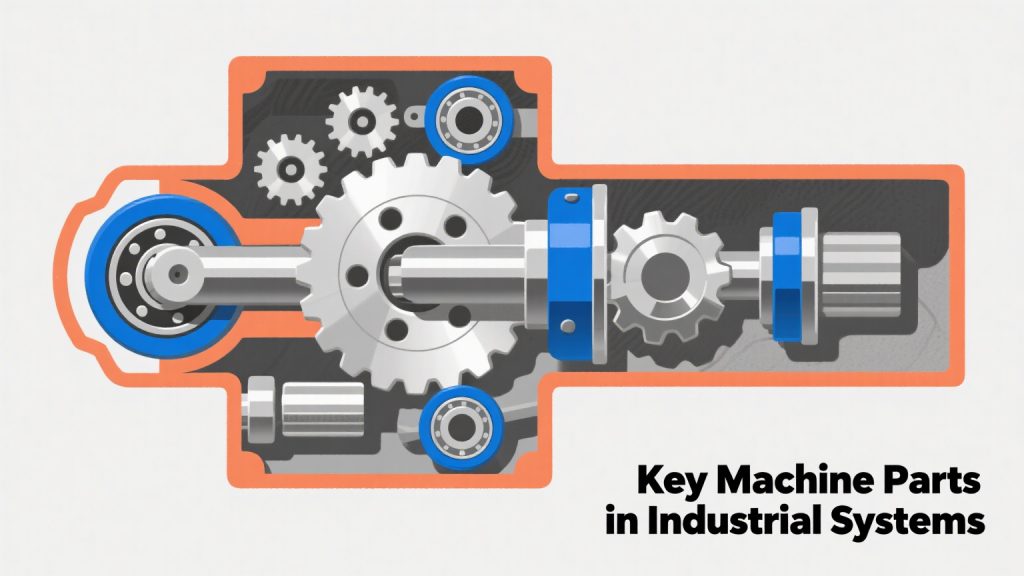

Mechanical Systems in Manufacturing: The Engine of Industrial Productivity

The manufacturing sector is where mechanical systems truly shine as the backbone of production. From automated assembly lines to heavy-duty CNC (Computer Numerical Control) machines, every piece of equipment relies on a symphony of mechanical parts-gears, bearings, shafts, and couplings-to execute precise, repeatable tasks. Without these parts for machines, even the most advanced factories would grind to a halt. Consider an automotive assembly plant: robotic arms that weld car frames depend on high-torque gears (a core machine part) to maintain accuracy, while conveyor belts use durable bearings (another critical mechanical part) to transport components seamlessly.

For manufacturers, the challenge lies not just in accessing these parts for machines, but in sourcing them reliably and cost-effectively. This is where Suntop becomes an invaluable partner. As a trusted ally to OEMs, ODMs, CEMs, and EMS companies worldwide, Suntop manages millions of component records-including mechanical parts-via its robust database, connecting clients to thousands of trading partners across dozens of countries. Its close relationships with major factories in North America, Europe, and Asia mean manufacturers never face delays due to missing machine parts; Suntop’s inventory management services ensure critical components are in stock, while its PPV cost-saving projects help reduce procurement expenses without compromising quality. The advantage here is clear: with Suntop’s support, manufacturers can keep mechanical systems running at peak efficiency, minimizing downtime and maximizing output.

Automotive Industry: Where Mechanical Systems Meet Precision Machine Parts

The automotive industry is a masterclass in mechanical system integration, with every vehicle relying on hundreds of interconnected components. From the engine’s crankshaft (a vital mechanical part) to the transmission’s clutches (key parts for machines), each element works in tandem to deliver power, control, and safety. Modern cars also incorporate advanced mechanical systems like anti-lock braking (ABS) and suspension setups, which demand ultra-precise machine parts to function reliably-even under extreme driving conditions.

For automotive manufacturers and repair shops, sourcing these mechanical parts is non-negotiable. A faulty bearing or worn gear can lead to catastrophic system failure, making quality and consistency paramount. Suntop addresses this need by leveraging its global distribution network to supply automotive clients with OEM-grade parts for machines. Whether a manufacturer needs bulk orders of piston rings or a repair shop requires a specialized sensor bracket, Suntop’s procurement services streamline the process. Its spot trading capabilities are particularly useful for urgent requests, ensuring that even hard-to-find mechanical parts are delivered quickly. By partnering with Suntop, automotive businesses gain a competitive edge: they reduce lead times, cut costs through PPV cost-saving projects, and ensure their mechanical systems meet the industry’s strict safety and performance standards.

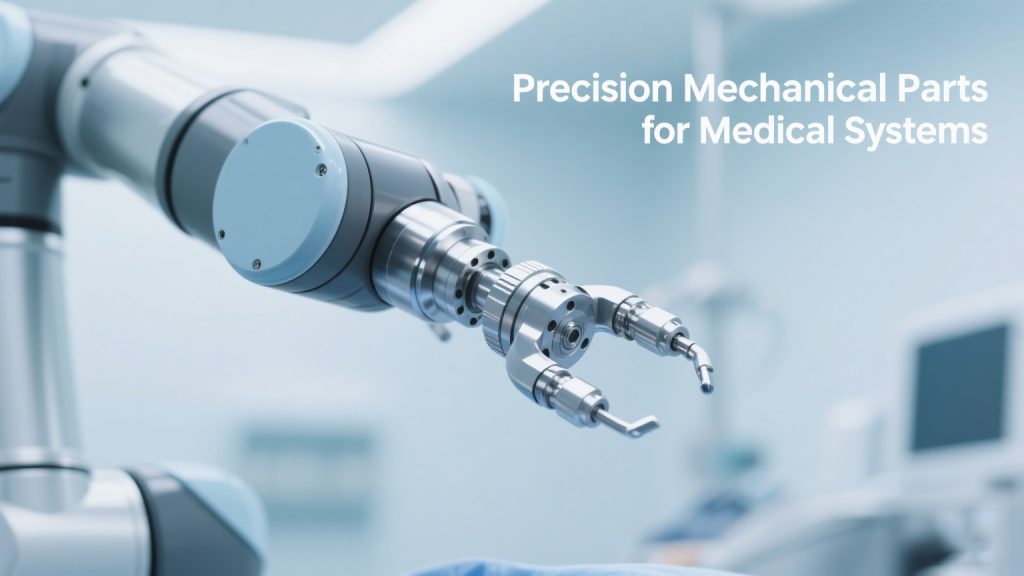

Medical Equipment: Mechanical Systems That Prioritize Safety & Sterility

In healthcare, mechanical systems are a matter of life and death, requiring machine parts that meet the highest standards of precision, sterility, and reliability. Surgical robots, for example, use micro-gears and linear actuators (specialized mechanical parts) to perform delicate procedures with sub-millimeter accuracy. Diagnostic equipment like MRI machines and ultrasound devices also rely on mechanical components-such as motorized tables and rotating scanners-that must operate flawlessly to produce accurate results.

For medical device manufacturers, sourcing these parts for machines is fraught with challenges: components must comply with regulatory bodies like the FDA, and any defect can lead to product recalls or patient harm. Suntop mitigates these risks by curating a selection of mechanical parts that meet global medical standards. Its professional team vets every supplier, ensuring that machine parts are manufactured to strict specifications. Additionally, Suntop’s inventory management services help medical companies maintain stock of critical components, preventing delays in device production. By partnering with Suntop, healthcare manufacturers can focus on innovating their mechanical systems, knowing that their parts for machines are safe, compliant, and readily available.

Aerospace & Defense: Mechanical Systems Built for Extreme Environments

The aerospace and defense sector demands mechanical systems that can withstand the harshest conditions-from the extreme temperatures of outer space to the high pressures of supersonic flight. Aircraft engines, for instance, use turbine blades (high-strength mechanical parts) that resist heat and corrosion, while military vehicles rely on ruggedized gears (durable parts for machines) to navigate rough terrain. In this industry, failure is not an option: a single faulty machine part can compromise a mission or endanger lives.

To meet these rigorous demands, aerospace and defense companies need a distributor that understands the unique requirements of their mechanical parts. Suntop rises to this challenge by partnering with specialized manufacturers in North America, Europe, and Asia that produce components for aerospace applications. Its database includes millions of machine parts records, allowing clients to quickly find hard-to-source items like titanium fasteners or ceramic bearings. Suntop’s PPV cost-saving projects also help defense contractors stay within budget, a critical factor given the sector’s tight funding constraints. By leveraging Suntop’s supply chain expertise, aerospace and defense businesses ensure their mechanical systems perform reliably-even in the most extreme environments.

Smart Homes & Consumer Appliances: Everyday Mechanical Systems You Use

Mechanical systems are not limited to industrial settings; they are also integral to everyday consumer products. Smart home devices like robotic vacuums use small motors and wheels (compact mechanical parts) to navigate floors, while washing machines rely on agitators and pumps (essential parts for machines) to clean clothes. Even kitchen appliances like blenders and coffee makers incorporate mechanical components-such as blades and gears-that enable their functionality.

For consumer appliance manufacturers, the key to success lies in producing affordable, durable products, which starts with sourcing high-quality parts for machines at competitive prices. Suntop supports this goal by offering a wide range of mechanical parts tailored to consumer electronics. Its inventory management services help manufacturers avoid overstocking, reducing storage costs, while its spot trading capabilities ensure that sudden spikes in demand are met. Whether a company needs plastic gears for a smart thermostat or metal shafts for a food processor, Suntop’s global network delivers the machine parts needed to keep production on track. The result? Consumers get reliable appliances, and manufacturers build trust in their brands.

Key Advantages of High-Quality Mechanical Parts & Partnering With Suntop

Investing in high-quality parts for machines is not an expense-it’s a long-term investment in the performance and longevity of mechanical systems. Inferior mechanical parts may cost less upfront, but they lead to frequent breakdowns, increased downtime, and higher repair costs over time. High-grade machine parts, by contrast, reduce maintenance needs, improve energy efficiency, and extend the lifespan of equipment. For example, a factory using premium bearings (a top-tier mechanical part) in its conveyor systems may see a 30% reduction in downtime compared to one using low-quality alternatives.

Partnering with Suntop amplifies these advantages. Unlike generic distributors, Suntop offers personalized solutions tailored to each client’s needs. Its PPV cost-saving projects analyze procurement processes to identify areas for savings, often cutting costs by 15-20% without sacrificing quality. Suntop’s inventory management services also eliminate the risk of stockouts, ensuring that critical parts for machines are always available. Additionally, its team of experts provides technical support, helping clients select the right mechanical parts for their specific mechanical systems. For businesses, this means less time spent on sourcing and more time focused on core operations-whether that’s manufacturing products, providing healthcare, or building aircraft.

Common Questions About Mechanical Systems & Their Parts

Q1: Which mechanical parts are most critical for industrial mechanical systems?

A: The most critical parts for machines vary by system, but core components include bearings (for reducing friction), gears (for transferring power), shafts (for supporting rotating parts), and fasteners (for securing components). These machine parts form the foundation of most industrial systems; a failure in any of them can disrupt operations. Suntop recommends regular inspections of these components and sourcing from trusted suppliers to avoid issues.

Q2: How does Suntop ensure the quality of the machine parts it supplies?

A: Suntop maintains close relationships with major factories and distributors worldwide, vetting each supplier for quality and compliance. Its database tracks millions of mechanical parts records, including certifications and test results, ensuring that every component meets industry standards. Additionally, Suntop offers quality assurance checks for high-volume orders, giving clients peace of mind that their parts for machines are reliable.

Q3: Can Suntop help with urgent requests for mechanical parts?

Yes. Suntop’s spot trading services are designed for urgent needs, connecting clients to in-stock parts for machines across its global network. Its team works around the clock to process orders, often delivering critical machine parts within 24-48 hours for emergency situations-such as a factory downtime or a medical device repair.

Q4: How do latest trends like Industry 4.0 affect the demand for machine parts?

Industry 4.0 (the rise of smart manufacturing) is increasing the demand for mechanical parts that integrate with digital systems-such as sensors embedded in gears or bearings with IoT capabilities. These “smart” mechanical parts allow for real-time monitoring of mechanical systems, reducing downtime and improving efficiency. Suntop is adapting to this trend by expanding its inventory of smart parts for machines and partnering with manufacturers that specialize in digital-ready components.

Latest Trends Shaping Mechanical Systems & Machine Parts Sourcing

The future of mechanical systems is being driven by three key trends: intelligence, sustainability, and miniaturization.

- Intelligent Mechanical Parts: As Industry 4.0 advances, more mechanical parts are being equipped with sensors and connectivity features. For example, “smart bearings” (a cutting-edge machine part) can transmit data on temperature and vibration, allowing operators to predict failures before they occur. Suntop is supporting this trend by adding smart mechanical parts to its inventory and helping clients integrate them into existing systems.

- Sustainable Components: With global focus on reducing carbon footprints, manufacturers are seeking parts for machines made from recycled or eco-friendly materials. Suntop has responded by partnering with suppliers that prioritize sustainability, offering recycled metal gears, biodegradable plastic fasteners, and energy-efficient motors. Its PPV cost-saving projects also help clients adopt sustainable sourcing practices without increasing costs.

- Miniaturization: In sectors like consumer electronics and medical devices, mechanical systems are becoming smaller and more compact—demanding tiny, high-precision machine parts. Suntop works with specialized manufacturers to supply micro-components like mini-gears and micro-bearings, ensuring that clients can innovate in small-form-factor design.

Conclusion

Mechanical systems are everywhere-powering factories, cars, hospitals, homes, and beyond-and their performance hinges on the quality of parts for machines, mechanical parts, and machine parts that drive them. For businesses looking to optimize their mechanical systems, partnering with a trusted distributor like Suntop is essential. With its 20+ years of experience, global network, and suite of services (including procurement, spot trading, PPV cost-saving projects, and inventory management), Suntop delivers the reliable, high-quality mechanical parts needed to stay ahead in a competitive market.

Whether you’re a manufacturer in need of bulk parts for machines, a medical company sourcing compliant machine parts, or an aerospace firm seeking extreme-environment mechanical parts, Suntop has the expertise and resources to support your goals. By prioritizing quality, efficiency, and client success, Suntop proves that the right partner can turn mechanical systems from operational necessities into drivers of innovation and growth.